Heat Transfer INK

EPTRANS-SCREEN HEAT TRANSFER INK (WATER-BASED)

MAJOR PROPERTIES

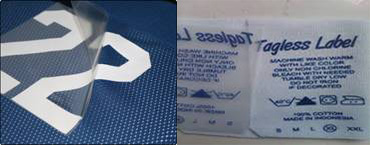

- High stretch water-based Transfer ink for ‘tag-less’ garment labels and sportswear

- Highly durable based on current brand wash requirements

- Oekotex 100 Class 1 Compliant

- Conforms to most major brand R.S.L (Restricted Substance Lists)

- ECO Friendly

- Excellent dye blocking capabilities when used in conjunction with EPTRANS-BB (Blocking Black)

- Soft Handling

USAGE

- Mix 2- 3 % of EPTRANS-HARDENER (Cross-linker) to EPTRANS inks (2-pack ink)

- Print the 2 Pack Ink EPTRANS ink colour required using desired screen e.g. 77, 90T.

- Dry the print at 110-120°C for 1 minute minimum using a drying tunnel.

- Apply second colour if required (between each colour) follow step 3 until final colour applied.

- Scatter Hot-melt adhesive powder into the wet EPTRANS- print (advisory to use a Polyurethane hot-melt adhesive powder for best stretch results)

- Shake/vacuum off excess adhesive power.

- Dry the final prints at 140°C for 1-2 minutes using a drying tunnel.

- If applying printable adhesive, follow steps 3 and 4 until print is dry then apply Printable Adhesive using 36T Screen. **Ignore Steps 5-6**

- Transfers requiring dye blocking properties, please apply EPTRANS-BB as the the final colour (step 3 and 4) best results is when product is printed using 34T screen or coarser.

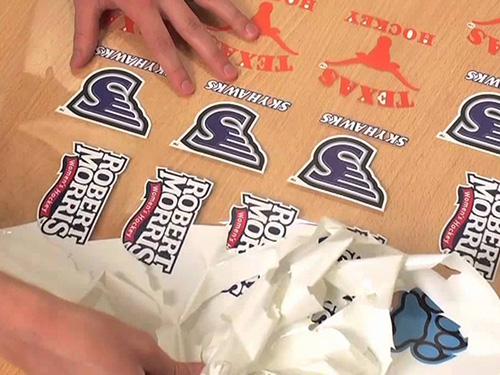

- Apply transfer onto garment setting the transfer press at the relevant time, temperature and pressure (advised by Adhesive supplier)

- Remove film/paper from the garment after ‘transfer’ application (hot or cold peel dependant on paper/film release recommendations.

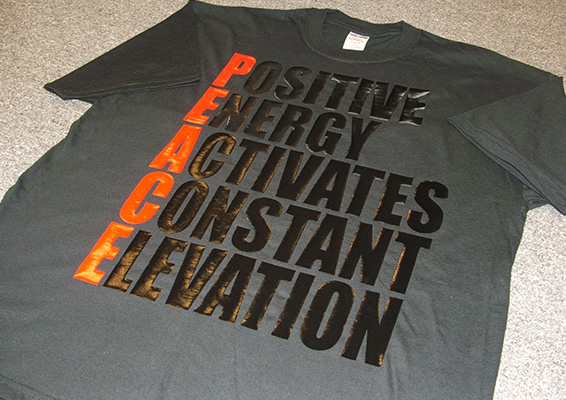

- You now have a super-stretch, super-resistant and brand compliant Screen Heat Transfer

**Any unused 2 PACK Ink (EPTRANS-WHITE + EPTRANS-HARDENER) must be disposed of responsibly (See M.S.D.S)**

ADDITIVES

Ink too thick: Add up-to 5% water or EPTRANS -RETARDER Ink drying quickly in screen: Add up-to 5% EPTRANS -RETARDER Cleaning screens: Use warm water to remove excessive ink and then a cleaner containing minimum 5% Ammonia STORAGE Keep EPTRANS- Ink out of direct sunlight and between 5-20 Celsius when not in use, keep the container lid sealed when ink is not in use.cd